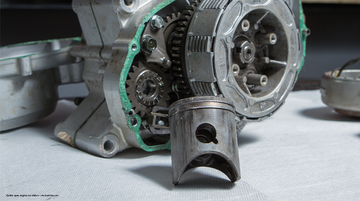

Piston rings from BARIKIT are available as rectangular rings, trapezoidal rings and L-rings, made of cast iron, steel and steel with chrome coating. The different materials and geometries all have advantages and disadvantages. In this blog post we have summarized the most important facts for you.

function

Piston rings have to fulfill the following tasks:

- Sealing the combustion chamber to maintain the pressure of the combustion gas; Avoidance of blow-by

- Dissipation of the heat occurring in the piston to the cylinder surface

- Centering the piston in the cylinder bore.

1.Piston ring: compression of the gas mixture and absorption of the gas pressure during the work cycle. Dissipation of the resulting heat.

2.Piston ring: Absorbs the remaining gas pressure as a result of blow-by. Control of the pressure conditions in the ring section and dissipation of heat in the ring section.

Requirements

The following requirements apply to piston rings:

- good running ability

- elastic behavior

- Mechanic solidity

- high heat resistance

- high thermal conductivity

Forces and stress

Piston rings are subjected to high mechanical, thermal and tribological stresses. They have to fulfill their tasks at high combustion temperatures and combustion pressures of up to 120 bar. Up to 20% of the heat absorbed by the piston is transferred to the cylinder bore through the piston ring.

Materials

As mentioned above, BARIKIT piston rings are made of cast iron, steel and chrome-plated steel. Piston rings made of cast iron have proven their worth for many years. Due to the high proportion of graphite in the cast iron, the rings have good emergency running properties. The demands placed on engines have continued to increase over the years, which is why the more brittle cast iron piston rings were replaced by steel rings. Steel rings are nitrided to increase surface hardness. The rings can be coated with chrome to reduce friction.

The selection of the piston ring geometry and the material depends on several factors. L-rings have increased contact pressure resulting from the gas pressure. However, these are exposed to high thermal loads. Trapezoidal rings have the property of preventing the ring groove from coking. The increased running-in clearance results in increased running noise. Cast rings have good running properties, but their mechanical properties are limited.

When selecting the rings, it is important that the material pairing between the rings and the cylinder surfaces is not identical, otherwise seizing will occur.

Due to the many possibilities, piston rings are individually adapted to each engine characteristic.

If you have any questions or would like individual advice, please give us a quick call or write to us by email or WhatsApp. We are glad to help you.

How did you like this article? Feel free to leave us a comment.