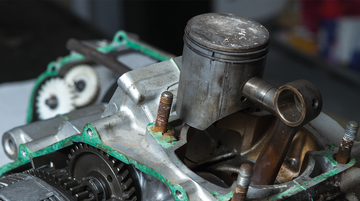

The piston pin is an underestimated component in your engine. So that you know what's behind it and can understand your engine better, we'll dedicate this article to this small but extremely important component.

function

The piston pin is the connecting link between the piston and the connecting rod. Due to the linear movement of the piston and the superimposition of gas and inertia forces, it is exposed to high loads in changing directions. The rotational movement of the connecting rod must be compensated for by the piston pin at the bearing points of the piston, in the piston hub and the small connecting rod eye.

Requirements

Piston pins must meet the following requirements:

- They should have sufficient strength and toughness to withstand the high loads without damage.

- In order to achieve favorable wear behavior, piston pins should have a high surface hardness.

- Piston pins should have a high form and position tolerance in order to achieve optimal adaptation to the contact surfaces of the piston and connecting rod.

- The weight of the piston pins should be as low as possible in order to keep the mass inertia lower.

- To avoid overstressing in the piston hub, piston pins should also have high rigidity (high resistance to external load).

Below are some additional facts about the requirements mentioned:

strength

Due to the forces acting, the piston pin is subjected to bending, ovalization and shearing. As a result, there is a requirement that the piston pin should be as stiff and light as possible.

deformation

The critical component of the piston connection is not the piston pin, but the piston. Ovalization (=elastic deformation) of the piston pin must therefore be as small as possible, otherwise the already heavily loaded piston hub will be overloaded and hub cracks can occur. Ovalization can be minimized by increasing piston pin diameters and increasing wall thickness, which contributes to increasing mass.

lubrication

Due to minimal lubrication of 2-stroke engines, the use of needle bearings for piston pin bearings is preferred. In 4-stroke engines, the use of plain bearings has become established due to the presence of spray oil and the higher gas forces. Oil pockets as reservoirs are possible to improve the build-up of a lubricating film.

Materials

Piston pins are made from case-hardened and nitrided steels. Hardening results in a high surface hardness with good wear behavior and good toughness in the core.

BARIKIT piston pin

BARIKIT piston pins are available in two versions. One with a cylindrical bore and one weight-optimized bolt with a conical bore. Here it is important to choose a compromise between the piston pins, as both variants offer advantages. With its reduced weight, the conical bolt is ideal for engines designed for higher speeds. However, these piston pins tend to ovalize more than piston pins with a cylindrical bore. At higher gas forces, the piston hub can be heavily loaded and, in the worst case, lead to the piston breaking. Therefore, piston pins with a cylindrical bore are suitable for engines with higher gas forces and torques. If you are unsure, please contact us via WhatsApp or email. You can find our contact details below. We would be happy to advise you.